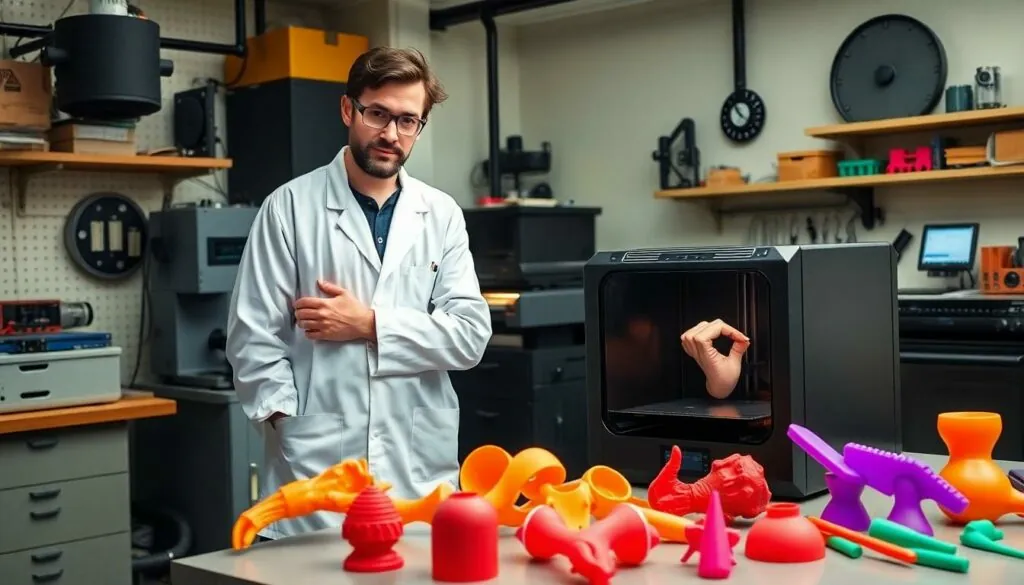

In a world where innovation meets creativity, 3D printing silicone is turning heads faster than a cat chasing a laser pointer. This game-changing technology isn’t just about making quirky gadgets; it’s about pushing the boundaries of what’s possible in design and manufacturing. Whether it’s crafting custom prosthetics or creating unique kitchen tools, the versatility of silicone in 3D printing is nothing short of magical.

Table of Contents

ToggleOverview of 3D Printing Silicone

3D printing silicone provides a unique approach to additive manufacturing. This material offers flexibility and durability, making it suitable for various applications. Custom prosthetics represent one of the most significant uses, allowing for personalized fittings that enhance comfort and utility. Industries utilize silicone for producing components that require intricate designs and superior performance.

Manufacturers often choose liquid silicone rubber (LSR) during the 3D printing process. LSR’s properties include high temperature resistance and biocompatibility, ensuring safety and functionality in medical applications. This material also supports a wide range of durometers, providing options for different hardness levels depending on product requirements.

Silicone molds created through 3D printing offer additional versatility. These molds facilitate the production of food-safe items, such as custom cake toppers and intricate kitchen tools. With superior heat tolerance, silicone molds can withstand high baking temperatures without compromising integrity.

The technology enhances design possibilities in consumer products. Designers create unique shapes and textures that traditional manufacturing methods may not achieve. High degrees of accuracy result in tailored products, boosting both aesthetic appeal and functionality.

3D printing silicone not only showcases innovative engineering but also addresses practical demands across multiple industries. By leveraging its properties, designers and manufacturers push the boundaries of creativity, leading to exceptional results.

Advantages of 3D Printing with Silicone

3D printing with silicone offers distinct advantages that enhance various applications. This technology stands out for its unique properties.

Flexibility and Durability

Flexibility characterizes 3D printed silicone, allowing for designs that bend and stretch without breaking. Durability ensures that products withstand wear and tear in demanding environments. Industries utilize this flexibility and durability for functional prototypes and end-use products. Items like wearable medical devices benefit from these traits, providing comfort and longevity. Additionally, silicone’s resistance to extreme temperatures enhances its application in industries requiring high-performance materials.

Customization Potential

Customization opens up opportunities in 3D printing with silicone. Each design can be tailored to meet specific user needs, providing a perfect fit for custom prosthetics. Complex shapes and unique textures are achievable, which traditional manufacturing methods often struggle to replicate. Users can adjust dimensions, colors, and properties according to specifications, enhancing user experience significantly. Ultimately, this customization leads to improved solutions in various fields, from healthcare to consumer goods.

Applications of 3D Printing Silicone

3D printing with silicone finds applications in various fields. Its versatility allows for innovative solutions across medical, industrial, and consumer markets.

Medical Use Cases

3D printing silicone revolutionizes the medical field. Custom prosthetics provide patients with personalized comfort and fit. Liquid silicone rubber offers biocompatibility, making it safe for implants and devices. Surgical tools can also be tailored to specific procedures using silicone. Wearable medical devices benefit from silicone’s flexibility, enhancing patient experience. Additionally, specialized anatomical models aid in pre-surgical planning, improving outcomes.

Industrial Applications

Industries utilize 3D printed silicone for mold creation. Production of complex shapes serves sectors such as automotive and aerospace. High-temperature resistance allows silicone parts to withstand harsh environments. These parts can be rapidly prototyped, significantly speeding up the development process. Seals and gaskets made from silicone contribute to machinery efficiency and reliability. Custom silicone components optimize manufacturing processes, enhancing functionality.

Consumer Products

Innovative consumer products emerge through 3D printing silicone. Kitchenware such as molds and utensils highlight silicone’s food-safe properties. Fashion accessories like custom-fit wearables showcase its potential for personal personalization. Gadgets benefit from silicone’s durability, making them perfect for everyday use. Toys designed with 3D printed silicone offer safe, flexible play options. This technology allows for unique textures and designs that captivate consumers, driving market trends.

Challenges in 3D Printing Silicone

3D printing silicone presents several challenges that impact its widespread adoption in various industries. Understanding these challenges helps businesses navigate potential limitations effectively.

Material Limitations

Silicone’s unique properties can pose material challenges. High viscosity often complicates the printing process, leading to flow issues in standard 3D printers. Some formulations lack the desired strength or flexibility, limiting their application. Additionally, certain silicones can exhibit poor adhesion to build surfaces, resulting in difficulties throughout multi-layer prints. Environmental factors, such as temperature and humidity, can further affect material performance, leading to inconsistencies in the final product.

Technical Barriers

Technical barriers also hinder the advancement of silicone 3D printing. Specialized equipment often requires significant investment, making initial costs high for many businesses. Compatibility issues arise between specific printers and silicone formulations, causing inefficiencies during production. Adjusting printer settings can prove complex, requiring expertise that may not be readily available. Furthermore, the limited availability of silicone-compatible software restricts design possibilities, challenging creators who seek to innovate with this versatile material.

3D printing with silicone is reshaping various industries by offering innovative solutions and enhanced customization. Its unique properties allow for the creation of flexible and durable products that meet specific user needs. As the technology continues to evolve, it promises to break down barriers in design and manufacturing.

Despite the challenges associated with material properties and technical requirements, the potential for growth in medical, industrial, and consumer markets remains significant. The ability to produce tailored items, from prosthetics to kitchen tools, highlights silicone’s versatility and importance in the 3D printing landscape. As advancements are made, the future of 3D printing silicone looks bright, paving the way for even more creative applications.